In today’s competitive food market, maintaining freshness and quality is critical for success. In seafood processing, the application of liquid nitrogen tunnel freezers has revolutionized the freezing of fish fillets. SPEEDCRYO has partnered with seafood companies for over 10 years, sharing expertise and offering diverse, professional solutions for various seafood processing needs.

Fish fillets, as a high-protein, low-fat healthy food option, are loved by consumers. However, ensuring their texture, nutrition, and quality during freezing is a challenging task. Traditional freezing methods often suffer from slow freezing rates and large ice crystal formation, which damages the cellular structure of the fillets, leading to a decline in quality and texture after thawing.

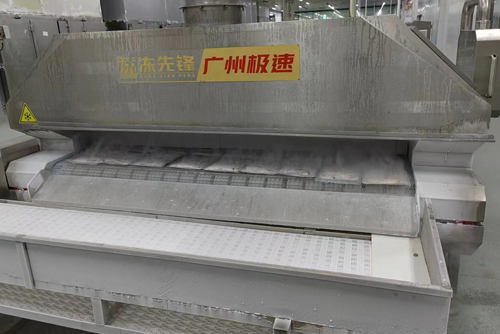

The advent of liquid nitrogen tunnel freezers effectively addresses these issues. These machines rapidly reduce the temperature of fish fillets to below -18°C in a matter of minutes, minimizing ice crystal formation and preserving freshness and texture to the greatest extent.

Using a continuous conveyor system, fish fillets are evenly placed on stainless steel belts at the inlet, with parameters such as freezing time and temperature precisely set. At the outlet, the system seamlessly integrates with downstream processes, achieving a highly automated production line.

Switching to liquid nitrogen freezing technology has yielded impressive results. The frozen fillets maintain vibrant color, clear texture, and tender, juicy flavor almost indistinguishable from fresh fish. This significantly boosts market competitiveness, resulting in substantial sales growth. For instance, processed fillets are vacuum-packed and frozen within 10-15 minutes per batch using the liquid nitrogen freezer.

The outstanding performance of liquid nitrogen tunnel freezers lies in their ultra-low operating temperatures, enabling nitrogen to penetrate fillets swiftly and freeze them uniformly. This forms small, evenly distributed ice crystals that preserve the food’s cellular structure. Additionally, precise temperature control systems allow adjustments based on factors such as fish species, thickness, and weight, ensuring optimal freezing results for every batch.

SPEEDCRYO boasts a professional team with over 10 years of experience in the refrigeration industry, holding 120+ cold chain technology patents. Its products are exported to more than 20 countries and regions. In 2021, SPEEDCRYO launched the construction of a 30,000-square-meter High-Speed Cold Chain Intelligent Equipment Manufacturing Industrial Park with a total investment of 160 million RMB. Completed by the end of 2023, the facility significantly enhances the company’s production capabilities and technical expertise, providing superior products and services to customers.

SPEEDCRYO remains committed to customer-centric solutions, offering comprehensive support tailored to individual needs. Our experts are available to answer any questions and provide free site planning services—because your success is our priority!

Nov 13, 2025

Nov 13, 2025

IPv6 network supported

IPv6 network supported